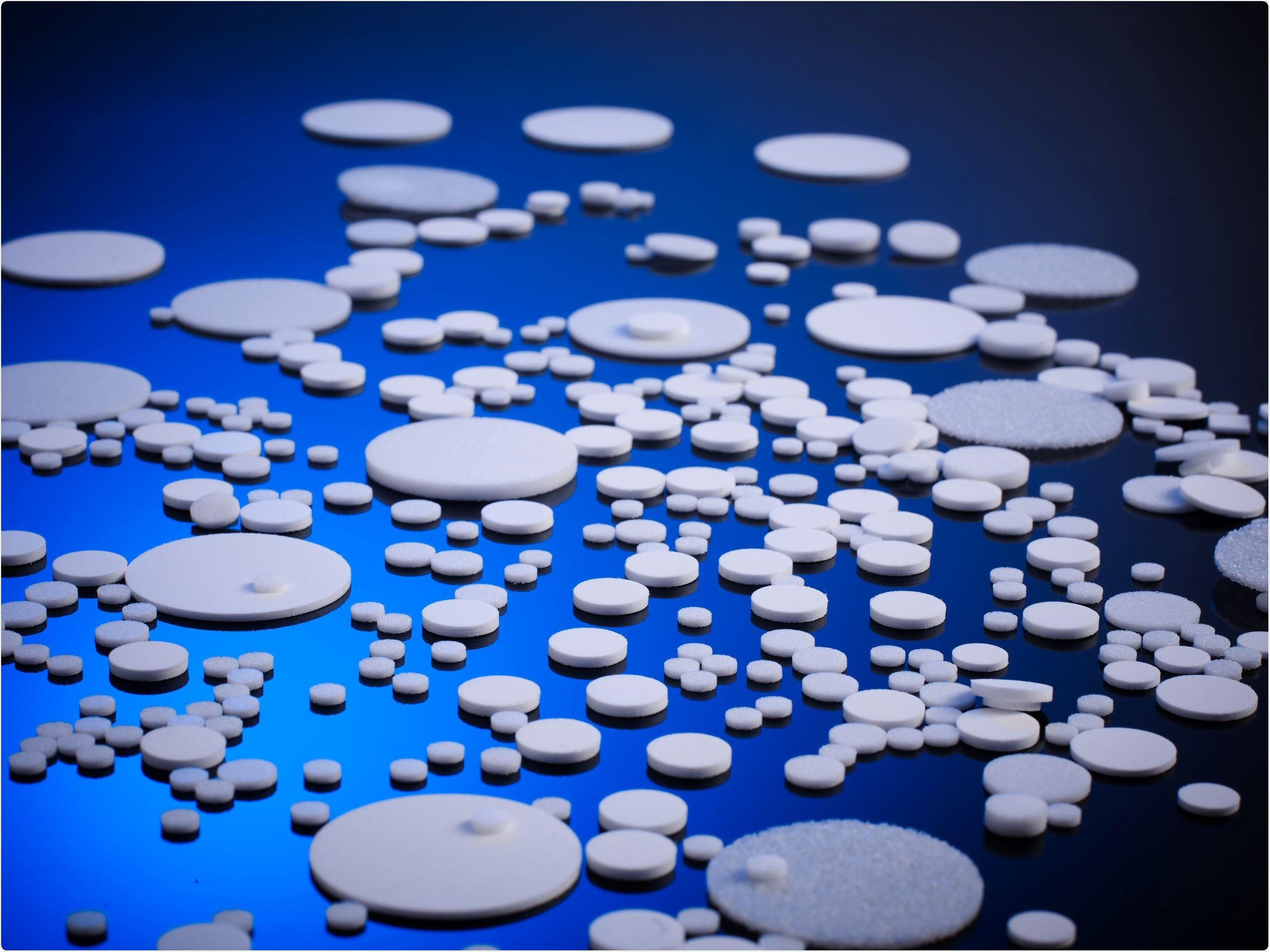

Porvair Sciences reports on the installation of new automated precision die-cutting equipment that has enabled a five-fold increase in its production capacity for porous plastic components.

This major investment by the company is in response to a significant rise in demand from customers for precision components made from its high performance Vyon® porous plastics. Installed in Porvair's cGMP compliant cleanroom production facility the new equipment is able to produce porous plastic components with excellent edge finish, cleanliness and repeatable tightly toleranced quality making it ideal for products such as pipette filter tips.

Available in polyethylene and polypropylene, Vyon® is manufactured with a controlled and even pore size distribution, ensuring consistent and efficient flow characteristics. This makes Vyon®ideal for a wide variety of filtration, separation and liquid handling applications in the healthcare, pharmaceutical and life science industries. Using regulatory approved polymer powders – Vyon® sintered porous plastic components exhibit exceptional chemical compatibility making them a popular material choice for analytical laboratory applications such as chromography sample preparation.

To discuss how Vyon® porous plastic materials can help improve your products performance, please contact Porvair Sciences Ltd on +44-1978-661144, [email protected] or visit https://www.vyonporousplastics.com/ for more information.